Why degreasing fume hoods is crucial

Degreasing professional hoods is essential to ensure a clean and safe working environment in professional kitchens. Fume hoods accumulate large quantities of greasy fumes and cooking particles which, if not regularly removed, can pose risks to safety, health and equipment performance.

Risks associated with an uncleaned hood network

A clogged hood network can have several serious consequences:

- Increased fire risk Grease deposits increase the risk of fire spreading.

- Blockage of filters and ducts Grease build-up reduces hood efficiency and may result in higher energy consumption.

- Hygiene problems Grease residues encourage the growth of bacteria and mould.

Degreasing methods for fume hoods

Preparation

- Initial assessment The team leader must examine the prevention plan and locate water, electricity and waste disposal connection points.

- Plant identification : Locate the installations to be cleaned and prepare the necessary equipment.

- Logging Electrical safety: Record electrical installations to ensure safety during work.

Cleaning ducts and extractors

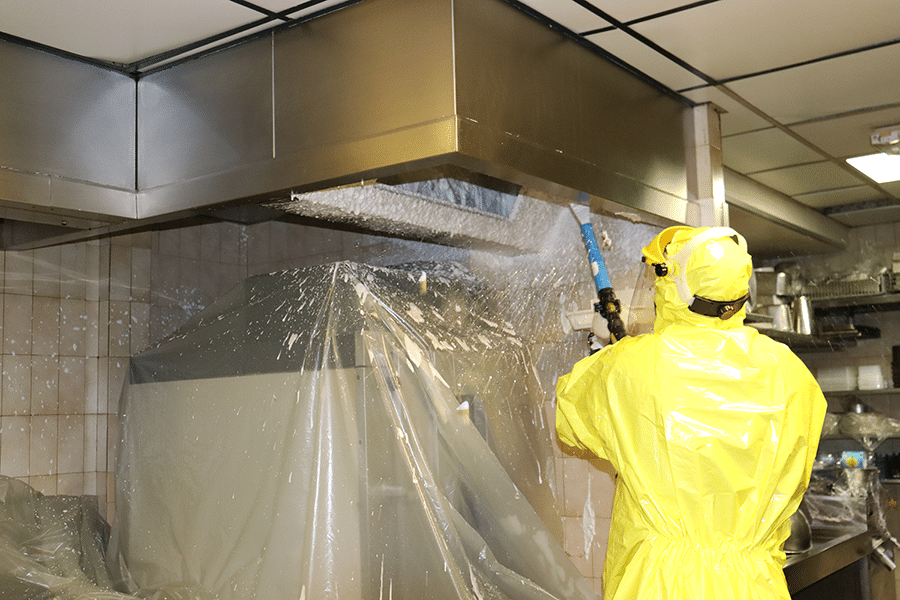

- Protection of the intervention zone Use polyane tarpaulins to protect surfaces and equipment.

- Network access Remove the false ceiling panels to gain access to the ducts.

- Application of detergents Use a foam gun to emulsify grease in the extractor turbine, and clean the ducts with a sprayer or foam gun.

- Dirty water recovery Use a wet vacuum to collect and dispose of dirty water.

- Rinsing and drying Rinse surfaces with hot pressurized water and dry thoroughly.

Hood cleaning

- Protection and detergent application Protect the environment with polyane film and apply detergent foam to surfaces.

- Rinsing and drying Rinse with hot water, vacuum residues and dry surfaces.

- Specific maintenance Clean UV lamps with a microfiber cloth if present, and polish hoods.

- Disinfection Disinfect work surfaces with a suitable disinfectant and dispose of waste.

- Cleaning equipment Clean and disinfect tools.

Compliance with regulatory standards

According to the’Order of October 10, 2005, In addition, extraction circuits must be cleaned regularly, at least once a year. It is also essential to keep a maintenance booklet up to date, and to ensure that ducts are fitted with appropriate inspection hatches.

Benefits of regular degreasing

Regular degreasing:

- Extends service life Increase the longevity of your equipment.

- Reduces the risk of fire Reduces the risk of grease deposits.

- Maintaining energy efficiency Improve the energy performance of your systems.

Choosing a professional degreasing service

Opting for a professional degreasing service ensures a thorough, standards-compliant cleaning. Experts use specialized equipment and follow best practices to guarantee optimal results.

Risks of DIY degreasing

Do-it-yourself degreasing may seem economical, but there are risks:

- Insufficient efficiency Inappropriate methods may not completely remove deposits.

- Plant hazards : Using unsuitable products can damage your equipment.

- Lack of conformity A safety register may not be kept up to date in the event of an inspection.

Impact on air quality

Cleaning hoods also helps to maintain good air quality in the kitchen. Be sure to replace air filters regularly to avoid vacuum problems and ensure a healthy environment for employees and customers.

Conclusion

Visit cleaning large kitchens, The degreasing of professional hoods is much more than a simple maintenance operation. It is essential to ensure the safety, efficiency and conformity of equipment in a professional kitchen. Implementing a regular cleaning program helps to maintain a safe and optimal working environment, while ensuring the longevity of your installations.

At IGIENAIR, an expert in air treatment, We offer professional degreasing services to ensure the compliance and performance of your installations.