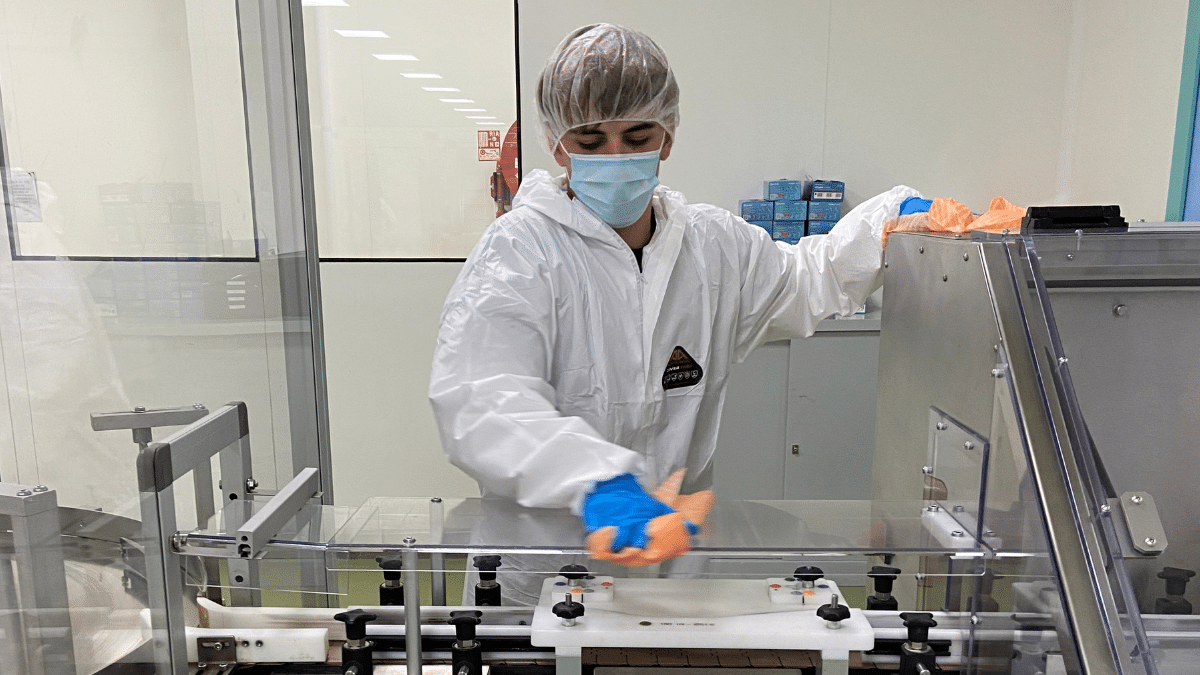

In ultra-controlled environments such as the clean rooms, Cleaning and disinfection are critical steps in ensuring the quality of the activities carried out. There are two key procedures for achieving these standards: the graying and the blanking.

They are often confused, yet their objectives are complementary. This article explains their differences, their role and their importance in the management of the particulate and microbiological contamination.

Greying: preparing surfaces

Visit graying is a preparatory stage cleanroom cleaning. It is generally carried out :

- before commissioning or installing sensitive equipment.

- after maintenance or construction work,

The steps involved in grayscale upgrading include :

- Stop ventilation

- Allows suspended particles to fall back.

- The air handling unit is then restarted to renew the air.

- Rough surface cleaning

- Walls, ceilings, floors and furniture are dusted.

- Use of suitable detergents

- Non-corrosive products, compatible with specific cleanroom surfaces.

| Result: a rough-cut environment, ready for a thorough disinfection treatment.

Greying is an essential phase in preparing the ground for the blanking. It ensures that surfaces are clean and free of any coarse particles that could interfere with final disinfection.

Blanking: the final disinfection step

After ’mise à gris", comes "mise à blanc". This more advanced operation aims to achieve a level of’ultra-clean. This step is mandatory before commissioning or restarting a cleanroom, especially after maintenance work or prolonged shutdowns.

Blanking steps include :

- Particle decontamination Surface decontamination: Surfaces are subjected to a fine decontamination process, removing not only visible particles, but also those not visible to the naked eye.

- Final disinfection Disinfection: This is the in-depth disinfection phase, in which all parts of the room (ceilings, walls, floors, supports, etc.) are treated to eliminate any microbiological or chemical contamination.

Blanking enables rooms to comply with current standards, such as NF EN ISO-14644 and NF S 90-351, and obtain their qualification or requalification. This step is crucial to ensure that the environment is perfectly controlled, minimizing the risk of contamination.

Why are these two steps essential?

Ensuring cleanroom quality and compliance. Greying and blanking are much more than just cleaning: they're about qualification procedures who :

- extend service life equipment

- guarantee the security for sensitive processes

- ensure regulatory compliance

Here are a few reasons why these steps are essential:

- Contamination prevention Cleanrooms are used in sensitive sectors such as pharmaceuticals and biotechnology, where the slightest contamination can have serious consequences.

- Compliance with standards : Greying and blanking operations ensure that rooms meet cleanliness and hygiene standards. indoor air quality required by regulators.

- Extending equipment service life By maintaining a clean environment, these steps also contribute to equipment longevity.

Invaluable expertise for clean rooms

Graying and blanking are essential to guarantee the quality and safety of controlled environments. They require expertise, suitable products and compliance with protocols.

Entrusting these operations to professionals is essential to ensure compliance and safety.

At IGIENAIR, We are experts in cleanroom qualification, decontamination and maintenance. We have the equipment and know-how to perform to the highest standards.

Contact our IGIENAIR experts for a free, personalized quote!