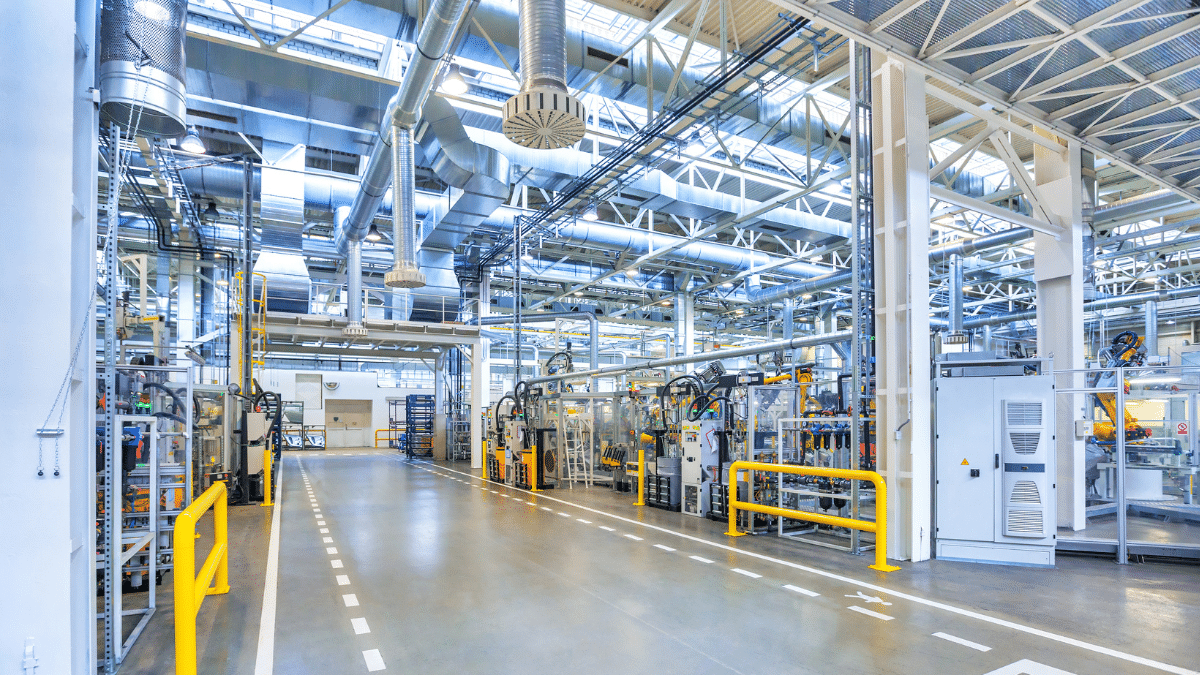

In industry, air treatment and the indoor air quality is a major issue for worker health and equipment performance. The presence of particles, dust, volatile organic compounds (VOCs) and other pollutants can affect not only employee well-being, but also plant productivity and safety.

This comprehensive guide to air treatment in industry will help you understand the challenges of air quality in the workplace, the different solutions available, and the best practices to adopt for a healthy and safe environment. compliant with current standards.

What is industrial air treatment?

Visit air treatment in industry encompasses all processes and systems designed to purify the air in industrial working environments. The aim is to eliminate or reduce pollutants, whether dust, oil mist, fumes or gases, to ensure the health of employees and the smooth operation of equipment.

The main industrial pollutants

Visit air pollutants vary from sector to sector. Here are the most common:

Industrial dust

From the wood, from cement, operations, or welding, they can cause respiratory diseases.

Oil mist

Issued at the’machining or the lubrication, they cause irritations and increase risk of slipping.

Volatile organic compounds (VOCs)

Present in solvents, paintings or chemical products, they are detrimental to health and the environment.

Toxic fumes and vapors

From the combustion or chemical treatments, they require specialist treatment.

Air treatment systems in industry: how do they work?

There are a number of air treatment systems to suit different types of pollutants and the specific needs of each industry.

Dust and particle filtration systems

Filtration systems, such as industrial dust collectors, capture fine particles and dust at source. Equipped with high-efficiency filters (HEPA, absolute), they ensure a high optimum air quality, particularly in metalworking, wood and cement plant. These systems are essential in environments such as the wood, cement and metallurgy industries.

Oil mist treatment

Oil mist emitted by machine tools must be treated with special industrial purifiers. This equipment filters oil droplets from the air, ensuring a clean and safe working environment.

Treatment of volatile organic compounds (VOCs)

For industries using solvents and chemicals, VOC treatment systems are indispensable. They often use activated carbon filters to capture and neutralize toxic and odorous gas emissions, ensuring a healthy, compliant working atmosphere.

Installation steps for industrial air handling systems

Installing an air handling system in an industrial environment is a multi-stage process, requiring specific expertise.

Needs analysis and identification of pollutants

Before installing a system, it's crucial to carry out a thorough analysis of the working environment. This step enables us to identify the types of pollutants present, their concentration, and the areas most at risk. This audit will serve as the basis for choosing the most appropriate solution.

Tailor-made solutions

Depending on the results of the audit, a customized treatment solution will be implemented. This involves selecting the most suitable equipment (dust collectors, purifiers, extraction systems, etc.) and filters (HEPA, activated carbon).

Installation and commissioning

The system must be professionally installed to guarantee its effectiveness. Once installed, the system is tested and adjusted to ensure optimum performance.

The benefits of good air treatment in industry

An efficient air handling system in industry offers many advantages, both for employees and for the company.

1-Improving workers' health

Removing pollutants from the air reduces the risk of respiratory illness, skin irritation and other health problems associated with poor air quality. A healthy work environment also enhances employee well-being and productivity.

2-Regulatory compliance

Industries must comply with strict air quality standards. A high-performance air treatment system enables these regulations to be met, avoiding fines and penalties.

3-Equipment protection and production optimization

Airborne pollutants can damage industrial equipment, leading to breakdowns and reduced productivity. An air treatment system helps keep machines running smoothly, reducing maintenance and downtime costs.

Choose the right air handling system for your industry

Industrial air treatment is crucial to employee health, equipment protection and regulatory compliance. As each industrial environment has its own specificities, it's essential to choose a treatment solution adapted to your needs.

Don't hesitate to call on air treatment experts to help you analyze, design and install efficient, sustainable systems.