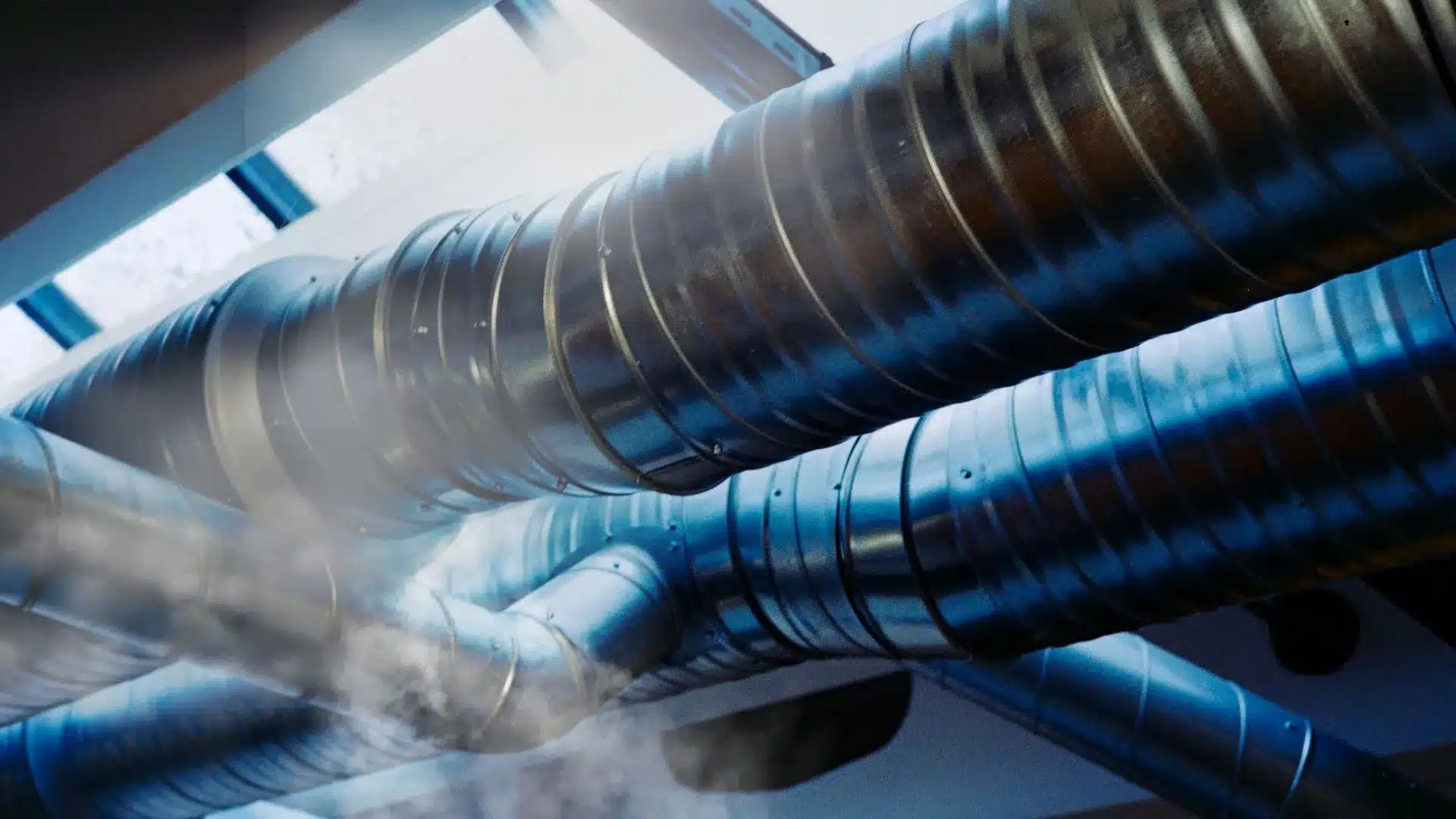

In commercial, industrial and healthcare buildings, energy performance and air quality are highly dependent on the condition of ventilation systems. Poorly sealed ducts often lead to excessive energy consumption and high operating costs. That's why Igienair offers ventilation network leakage testing to diagnose and improve the reliability of your installations.

Why leak-test ventilation systems?

In addition to regulatory requirements, leak testing of ventilation systems is essential for :

- Reduce energy losses due to pipe leaks ;

- Ensure proper air flow distribution on the premises ;

- Ensuring network hygiene avoiding the infiltration of dust or contaminants, particularly in the return networks; ;

- Optimizing maintenance and prevent system performance drift HVAC.

Certified, standardized expertise

Leak testing of ventilation systems is carried out in accordance with standards EN 12237, EN 1507 or EN 12599, depending on the type of system (circular or rectangular). Igienair relies on calibrated measuring equipment and a rigorous methodology that complies with the requirements of Qualibat 5221 qualification, an essential reference for the acceptance and inspection of ventilation systems.

The test protocol applied by Igienair

Our technicians intervene according to precise steps:

- Network preparation : sealing vents and terminal equipment (diffusers, grilles, dampers, etc.).

- Pressurization of the test section via a test fan.

- Leakage rate measurement by comparing the flow rate injected and the pressure obtained.

- Comparison with sealing classes (A, B, C or D) depending on the flow rates measured.

- Detailed report with action plan, results and recommendations for retrofitting if necessary.

Typical applications

Our tests can be applied in a variety of contexts:

- New installations in the technical acceptance phase (hospitals, laboratories, tertiary buildings, schools); ;

- Existing networks as part of refurbishments or energy performance audits; ;

- Hygienization or IAQ compliance operations ;

- Regulatory monitoring in constrained environments (cleanrooms, operating theatres, pharmaceutical or food processing industries).

The key stages of an airtightness test

How does an airtightness test work in practice? At Igienair, we follow a rigorous protocol to guarantee reliable results. Here are the steps we follow for your home airtightness test.

Orifice sealing

To measure only unintentional leaks in the network, we systematically seal all supply and extraction ports.

- For networks fitted with terminal filters (HEPA, high-efficiency filters): The filters are temporarily removed and replaced by galvanized metal plates, ensuring a perfect seal during the test.

- For tertiary networks (supply/extraction grilles): Grilles are sealed with suitable plates or watertight tarpaulins, securely fastened to prevent any parasitic leakage.

This step is crucial: only leaks in the network itself (ducts, fittings, bushings) need to be measured, not those linked to terminals.

Setting up measurement equipment

We use a calibrated measuring fan, connected to a precision pressure gauge, to create a controlled pressure difference in the network (generally 400 Pa, in accordance with standard NF EN 12599).

- The fan is connected to a dedicated measuring port or to a specific network port.

- The tightness of the connection is checked before any measurement.

Leak detection

Once the system has been installed and the network pressurized, we can locate leaks using :

- A smoke generator Air flow: to visualize air flows escaping through leakages.

- A thermal camera reveals temperature variations due to air infiltration.

- Manual control Our technicians inspect fittings, wall penetrations and assemblies.

Leakage rate calculation

Leakage rate is measured in m³/h for a given pressure (400 Pa). This result is compared with the tightness classes defined in standard NF EN 12599 (classes A to D). Example A Class B network must have a leakage rate ≤ 0.027 m³/(s.m²) at 400 Pa.

Results analysis

The data is analyzed and presented in a detailed report, including :

- Visit overall leakage rate network.

- Visit location of major leaks.

- From technical recommendations (clogging, seal replacement, etc.).

This report enables project owners, inspection bodies and operators to validate the conformity of the system, particularly in the context of the acceptance of HVAC installations.

Igienair: your partner for a compliant network

Professional buildings, whether hospitals, industries or offices, must guarantee not only impeccable air quality, but also optimum energy efficiency. Indeed, if ventilation networks are not perfectly airtight, they can lead on the one hand to considerable energy losses (up to 30 % according to ADEME, 2021) and, on the other, to major health risks linked to cross-contamination.

Consequently, air-tightness is not an option, but a regulatory and technical requirement. That's why Igienair, with its expertise in measurement and control of ventilation networks, is the partner of choice to support maintenance managers, hygienists and manufacturers in this process.

Why choose a qualified company ?

First of all, ventilation systems in the workplace are subject to specific standards and regulations, such as :

- Standard NF EN 12599, which defines methods for measuring the tightness of air networks; ;

- Standard NF EN 16798 on performance requirements for ventilation systems; ;

- Qualibat 5221 qualification, essential for carrying out compliant measurements in the workplace; ;

- Haute Autorité de Santé (HAS) guides, particularly for medical establishments (operating theatres, laboratories).

What's more, these requirements are not just about compliance, but also about health safety and optimizing energy costs. Poorly sealed ventilation systems can lead to :

- Significant energy losses, as treated air (heated, cooled or filtered) escapes instead of reaching the premises; ;

- An imbalance in pressure, which can lead to uncontrolled air infiltration or, conversely, to overpressure that is detrimental to air quality.

The health consequences should not be overlooked. The spread of contaminants (pathogens, fine particles, VOCs) can occur if leaks allow cross-contamination between premises. Non-compliance with standards (HAS, ISO 14644) entails legal risks and penalties in the event of an inspection.

In the final analysis, faulty waterproofing is not just a technical problem, but also an economic, health and regulatory issue.

Services offered by Igienair

Drawing on its experience since 2003, Igienair offers a complete range of services related to indoor air quality. Our expertise in leak testing is part of a global approach that includes the sealing of ventilation networks. These services are deployed by our 730 employees in over 40 agencies across France, ensuring optimum proximity and responsiveness.

On-site and post-site intervention

Our experts are involved at every stage of your project. During the construction phase, we carry out intermediate checks to identify and correct any leaks before they become a problem. In the post-construction phase, we carry out the final measurements and deliver the reports needed to validate your aeraulic projects. Our pragmatic approach guarantees reliable, compliant results.

Conclusion

In commercial, industrial and healthcare buildings, the tightness of ventilation networks is a key factor in guaranteeing energy performance, air quality and regulatory compliance. As we have seen, poor sealing can lead to energy losses of up to 30 %, pressure imbalances and health risks (cross-contamination, spread of pathogens). Igienair, with its expertise and standards-compliant methodology EN 12599 and Qualibat 5221, offers rigorous tests to diagnose and correct these defects.

Our protocol, from sealing terminals to measuring leaks, enables us to accurately identify leaks and provide appropriate recommendations for optimal compliance. Whether for new installations, refurbishments or audits, our work covers all professional contexts, from hospitals to industry and tertiary buildings.

Beyond compliance, our tests help to reduce energy costs, improve indoor air quality and secure your installations over the long term. With over 40 agencies in France, Igienair guarantees optimum responsiveness and customized support, from the construction phase through to operation.

To find out more about regulatory requirements and best practices, consult the ADEME recommendations (link) and the Haute Autorité de Santé guides (link).

When you choose Igienair, you're choosing an expert partner capable of guaranteeing the compliance, performance and safety of your ventilation systems. Contact us for a personalized diagnosis and solutions tailored to your needs!